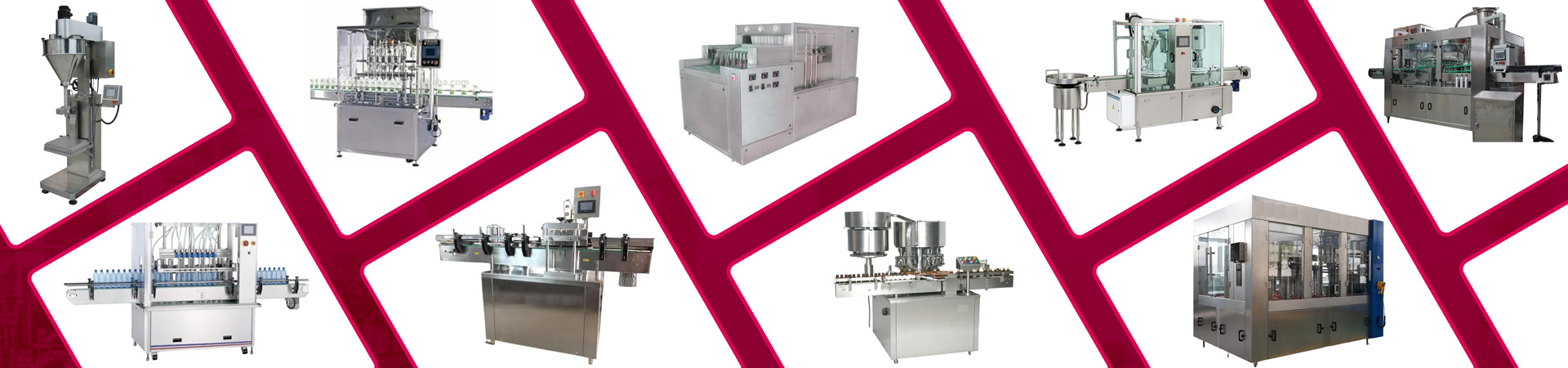

In today's fast-paced manufacturing environment, efficiency and precision are paramount. VIBGYOR offers a comprehensive range of high-quality automatic liquid filling machines designed to streamline your production processes and enhance productivity. As a leading automatic liquid filling machine manufacturer in Ahmedabad, we are committed to providing innovative solutions that meet the diverse needs of industries across India.

Why Choose VIBGYOR for Your Liquid Filling Machine Needs ?

Unparalleled Quality : Our automatic liquid filling machines are crafted with precision and using the finest materials, ensuring long-lasting durability and reliable performance. We adhere to stringent quality control standards to deliver products that exceed your expectations.

Customization Options : We understand that every industry has unique requirements. Our team of experts works closely with you to customize our machines to fit your specific needs, ensuring optimal efficiency and compatibility with your existing production lines.

Advanced Technology : VIBGYOR incorporates the latest technological advancements into our liquid filling machines. From touch screen controls to automated safety features, our machines are designed to enhance productivity and minimize downtime.

Comprehensive After-Sales Support : We are committed to providing exceptional customer service. Our dedicated support team is always available to assist you with installation, maintenance, and troubleshooting. We offer comprehensive after-sales support to ensure the smooth operation of your machines.

Competitive Pricing : VIBGYOR offers competitive pricing for our automatic liquid filling machines without compromising on quality. We believe in providing value for money and helping you achieve your business goals.

Experience the Benefits of Automatic Liquid Filling Machines

By investing in an automatic liquid filling machine from VIBGYOR, you can enjoy numerous benefits, including :

Increased productivity : Automate repetitive tasks and reduce labour costs.

Improved accuracy : Ensure consistent filling levels and minimize product waste.

Enhanced efficiency : Streamline your production processes and optimize resource utilization.

Enhanced safety : Minimize the risk of human error and accidents.

Improved product quality : Maintain consistent product quality and meet regulatory standards.