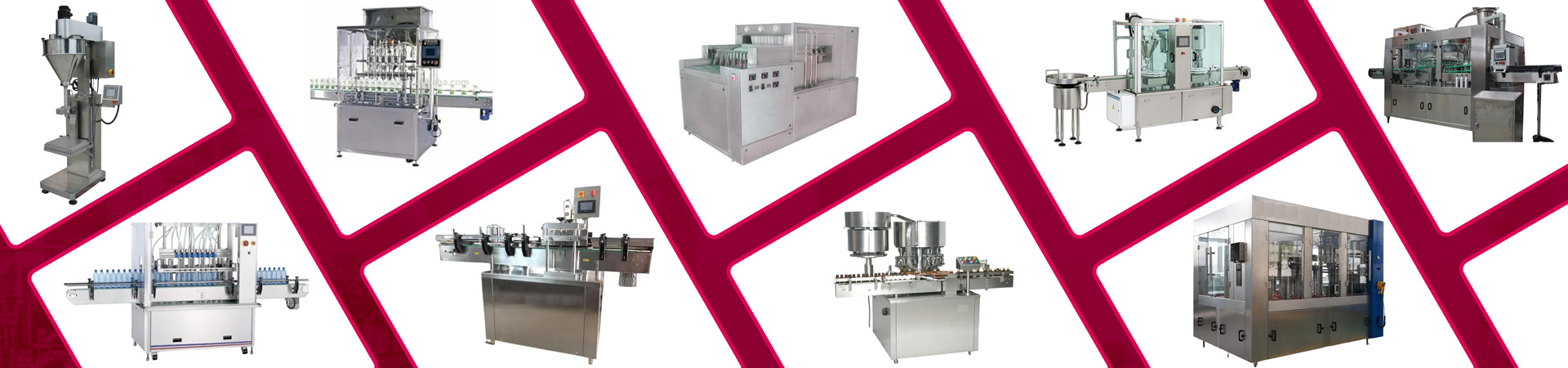

Product Overview:-

Machine is suitable for Glass, Plastic, PET, HDPE and LDPE Bottles with maximum speed of 60 to 120 Bottles per minute depending on Powder Fill Volume, Type of Powder, Bottle Diameter and Bottle Neck Diameter.

Machine equipped with heavy duty frame structure with Stainless Steel Cladding. All parts coming in contact with Powders are made from Stainless Steel 316 Materials as well as HDPE Funnels. The Machine works on proven time-tested Vacuum and Air Systems to fill powder in Bottle reaching higher speed and higher accuracy. Mechanism having unique Bottle Lifting and Neck Holding system avoid spillage of powder on bottle shoulder, neck and body keeps bottle clean and also avoid wastage of powder.

Machine with complete synchronization of Bottle In-feed Star Wheel, Powder Wheel movement and out-feed Star wheel for smoother operation. Machine with Rotary Bottle Moving system ensures very high-speed powder filing through independent moving funnel along with bottles for greater speed and performance without compromising speed and fill accuracy. Machines with unique vibratory system inside the funnel helps filling of semi free flow type powder at higher speed.

Features:-

- CGMP model based on advanced technology

- Heavy duty M.S. molded structure for vibration-free operation

- No Bottle No fill system to avoid wastage of costly powder

- Spring loaded Teflon top seal for powder hopper reduces the friction between powder wheel and top seal and avoid chance of white particle shading during operation.

- Adjustment of Doctor Blade and Wiper blade can made from outside without interrupting production saving time, powder wastage and chances of area condition disturbance.

- Separate Variable Drive to control speed of conveyor

- All drives through imported gear motor.

- All contact parts and assemblies are of SS 316

- Easy maintenance and cleaning as all assemblies are under top plate

- Dry Powder Filling Line Machine is provided with delrin conveyor belt to avoid sticking of bottle on conveyor.

- Special clutch devices are provided on star wheel for safety purpose.

- Air filter of SS 316 housing with Nylon cartridge for proper removal of particle of 0.22 micron having 10” length.

- Vacuum filter of PVC transparent material with nylon cartridge f 10” length of 5 micron.

- Dry Powder Filling Line Machine can fill 10 gm. to 50 gm. powder in single stroke.

- Imported Motor for Main drive

- A.C. Frequency drive for Main drive

- Pure air filters for Air and Vacuum

Specification:-

| Model | VEDSF80 | VEDSF100 |

| Bottle Diameter | Up to 85mm*, | Up to 85mm*, |

| Bottle Height (mm) | 100 | 100 |

| Cap | 22,25,28 mm | 22,25,28 mm |

| Fill Range | 5 gm. to 70 gm. | 5 gm. to 70 gm. |

| Bottle | Glass / HDPE | Glass / HDPE |

| Fill Accuracy | ±2 % depends on Humidity | ±2 % depends on Humidity |

| Electrical | 415VAC 3Phase 220VAC Single Phase 55 Hz | 415VAC 3Phase 220VAC Single Phase 55 Hz |

| Power | 6 HP | 6 HP |

| Air Pressure | 6 bar pressure 0.5 CFM | 6 bar pressure 0.5 CFM |

| Vacuum Line | 28 HG | 28 HG |

| Conveyor Height | 815-940 mm | |

| Dimension | 1900 (L) X 1200(W) X 2000(H) | 2000 mm (L) x 1200 mm (W) x 1800 mm |

| Speed | 80 BPM | 120 BPM |

Note:- specification can be entertained as per customer’s requirement.

Vibgyor is a renowned manufacturer of Rotary Vaccumatic Dry Syrup Filling Machines. With a strong focus on innovation and quality, our company has established itself as a leading player in the pharmaceutical machinery industry. Our Rotary Vaccumatic Dry Syrup Filling Machines are designed to meet the stringent requirements of the pharmaceutical sector, offering precise filling of dry syrup in a sterile environment. With advanced features such as automatic bottle feeding, vacuum and nitrogen flushing and accurate filling controls, these machines are trusted by pharmaceutical companies worldwide. Vibgyor commitment to excellence in design, manufacturing and customer service has made them a preferred partner for pharmaceutical machinery solutions.