Overview:-

The Mechanism works on attitude of back compression of Bottle, which will be served by the Turn Table to the conveyor where one star plate is given which is functioned automatically has specified clutch for avoid the mutilation. Purpose of the star plate to thrust the bottle into inverter, There are three sector first is inverter which inverse the bottle second is cleaning segment where the air pressure is to be supplied & vacuum segment is to be given where the dust is to be collect in a vacuum section and it is to be attached with dust extractor to remove the dust after procedure bottle is to be move in into third zone (inverter) which transforms the bottle into real Position for the next operation.

Features:-

- Centrifuge is used to preserve timing between two bottles.

- Stainless Steel Pressure Gauge.

- Stationary Stainless Steel jets.

- Positive air pressure and vacuum cleaning.

- Isolated control for air pressure

- High efficient blower to clean bottle properly

- Physical loading and automatic unloading bottle

- Stress-free operating system

- Pressure switch specified for locale of preferred pressure

Specification:-

| Model | VELA80 | VELA120 |

| Bottle Neck Dia. | Ø 22 to 28 mm | Ø 22 to 28 mm |

| Bottle Height | 50 to 200 mm | 50 to 200 mm |

| Bottle Diameter | Ø 32 to 80 mm | Ø 32 to 80 mm |

| Output/ Hour | 2400 to 4000 | 3600 to 7200 |

| Direction of Machine** | Right to Left | Right to Left |

| Electrical | 1 HP / 415 Volts / 50 Hz | 1.5 HP / 415 Volts / 50 Hz |

| Power | 2 HP | 2.5HP |

| Air Pressure | 6kg/Cm2 | 6kg/Cm2 |

| Cleaning Cycle | Air Pressure (Positive) & Vacuum (Negative) | Air Pressure (Positive) & Vacuum (Negative) |

| Working height | Adjustable 860 to 910 mm | Adjustable 860 to 910 mm |

| Dimension (mm) | 2600(L) X 1000 (W) X 1150(H) | 2600(L) X 1000 (W) X 1150(H) |

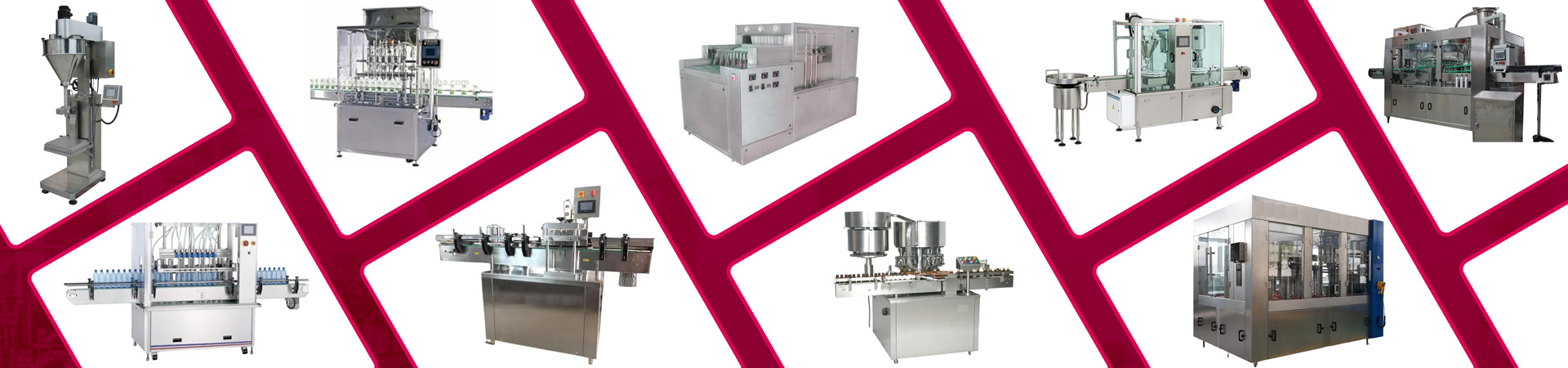

Vibgyor is a leading manufacturer of linear airjet cleaning machines, catering to the diverse needs of industries across the globe. With a strong focus on quality and innovation, our company has been providing cutting-edge solutions for airjet cleaning of various products. Our state-of-the-art machines are designed to provide efficient and effective cleaning solutions for a wide range of applications. Vibgyor commitment to customer satisfaction, timely delivery and competitive pricing has helped them earn a reputation as a trusted partner in the industry.

Note:- specification can be entertained as per customer’s requirement.