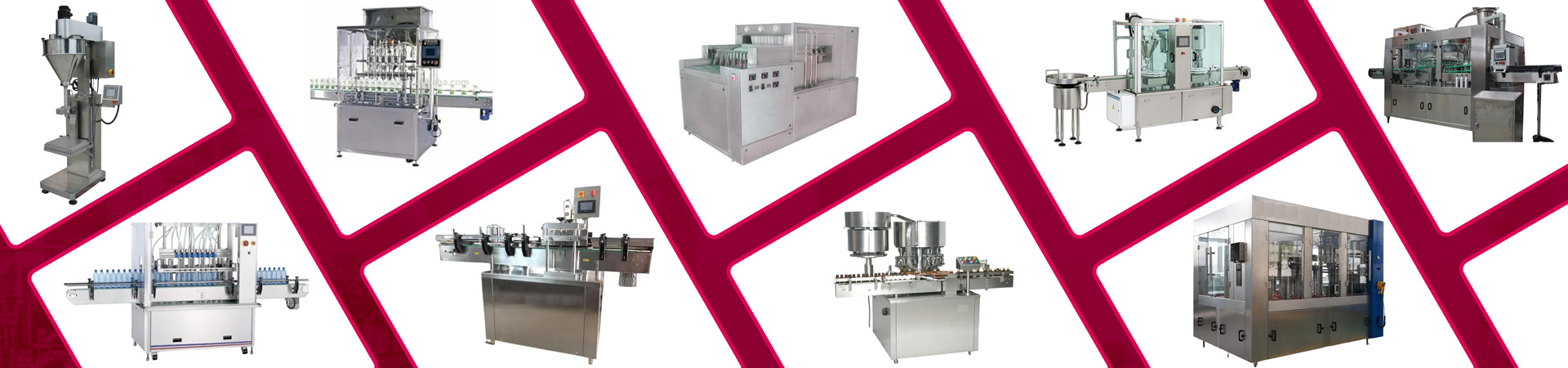

Product Overview:-

Automatic Two Head Monoblock Machine for filling different type of liquids. We are providing different type of range in particular segment. Foaming Liquid, Viscous solution products. We can fill PET, Plastic, Glass, Aluminium, Stainless Steel, Copper, jars, containers and solid packaging types can be filled with VIBGYOR Liquid Bottle Filling Machine. The Primary Unit consists of base structure, stainless steel slat conveyor belt, piston pump and filling needles the speed of bottle filling machine depends on nature of liquids, diameter height neck size and volume of product. Machine construction dully stainless Steel with GMP guidelines. Machine will available with optional TURN TABLE at In-feed and Out-Feed stations with individual drives to control speed of bottles and smoother operations.

About Machine Design, We will design Layout for Customer according to Customer’s Factory Space, L Shape, U Shape, and Linear Shape. Filling Machine Top with tank to store Material, with Protect Cover.

Application:-

Machine applicable in various Industries i.e. Water, Liquor, Oil, Spirit, Vinegar, Sauces, Juice elements, Jams, Yogurt, Milk, Mayonnaise, salad creams, oil, Carbonated Soft drinks, sparkling wine, honey, cosmetic creams, waxes, solvents, inks, alcohol, spirits, Ghee, Corrosive Liquids, Bleaches, Sanitizer, Agriculture Pesticides, Adhesive Liquid, Mustard Oil, Coconut Oil, leech Oil, olive Oil, Peanut Oil, Soybean Oil, Sunflower Oil, Cooking Oil, Vegetable Oil, Canola Oil, Avocado Oil, Sesame Oil, Creams, Ointments, Paste, Lotions, Solution Cosmetic, Ethanol, Methanol, Acetone, Toluene, Methyl acetate, Ethyl acetate.

Features:-

- Precision and High Speed with Good Stability

- High Speed filling is used in the initial stage of filling, when Filling Volume is close to target, slow filling can be used to prevent Liquid overflow pollution bottle mouth.

- Easy to adjust, Filling Specification only needs to change the parameters on the Touch Screen Monitor.

- Suitable for all kinds of Viscosity Filling.

- Rigid Vibration and Noise free Performance

- Each & Every Filling Head operated and Monitored through PLC Individually.

- Filling Nozzle into the Bottle neck and slowly move up to avoid Bubbling.

- Low Space Occupancy and Low Liquid Level receiver, Easy to clean.

- Filling system has the function of Shrinkage, No Drip Leakage

- The Machine is designed according to GMP Requirement.

Specification:-

| Model | VE2MBC40 |

| Liquid Filling Volume | 50 ml to 5 Ltr PET/HDPE Bottles/Jars |

| Constructed Filling Head | Two Heads |

| Constructed Capping Head | Single Head |

| Filling Accuracy | <0.5 % |

| Power Supply | 3 Phase + Neutral + Earthing/415 V AC/50 Hz |

| Power Consumption | 3 HP |

| Conveyor Height | 8 Feet (Can Be extend ) |

| Air Supply | 4 to 6 Kg/Cm2 |

| Feeling Principle | Pressure |

| Filling Advantage | Anti-Dropping |

| Control | PLC |

| Output Production Speed | 40 BPM |

| Output Capping Speed | 40 BPM |

| Transport Package | Standard Packing (Domestic/Export) |

| Trademark | VIBGYOR |

| HS Code | 8422 |

Note:- specification can be entertained as per customer’s requirement.