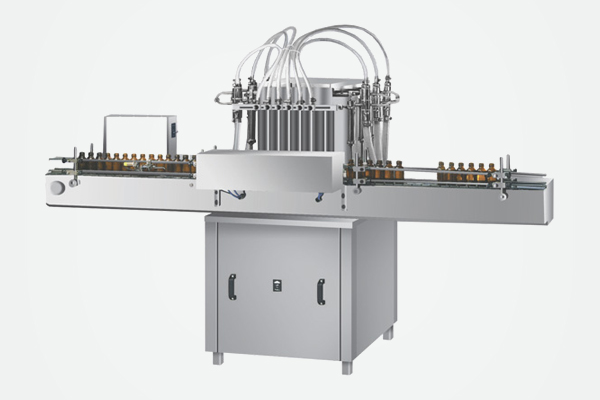

In today's fast-paced manufacturing industry, efficiency and accuracy are paramount. VIBGYOR stands out as a leading supplier of automatic liquid filling machines in Hyderabad, offering innovative solutions that streamline your production processes and enhance your overall productivity.

Why Choose VIBGYOR as Your Liquid Filling Machine Supplier ?

State-of-the-Art Technology : Our automatic liquid filling machines are equipped with advanced technology, ensuring precise and consistent filling of various liquids. From viscous fluids to highly volatile substances, our machines can handle a wide range of products.

Customized Solutions : We understand that every business has unique requirements. Our team of experts works closely with you to design customized liquid filling machines that perfectly suit your specific needs, whether you're dealing with small-scale operations or large-scale production.

Uncompromising Quality : VIBGYOR is committed to delivering the highest quality products. Our machines are built using premium-grade components and undergo rigorous testing to ensure durability, reliability, and optimal performance.

Comprehensive Support : We provide comprehensive after-sales support, including installation, maintenance, and troubleshooting services. Our dedicated team is always available to assist you and address any queries you may have.

Competitive Pricing : VIBGYOR offers competitive pricing for our automatic liquid filling machines without compromising on quality. We believe in providing value-added solutions that help you maximize your return on investment.

Experience the Benefits of Automatic Liquid Filling Machines

By investing in an automatic liquid filling machine from VIBGYOR, you can enjoy numerous benefits, including :

Increased Efficiency : Our machines automate the filling process, reducing manual labour and increasing overall production efficiency.

Improved Accuracy : Precise filling ensures that every product meets the desired specifications, minimizing waste and enhancing product quality.

Enhanced Productivity : With faster turnaround times and reduced downtime, our machines help you increase your output and meet customer demand.

Cost Savings : By automating the filling process, you can reduce labour costs, minimize product wastage, and improve overall operational efficiency.